As a Christmas/New Year's present, I got myself a 3D printer. I had been toying with the idea of getting one for a while, but I never really jumped to it.

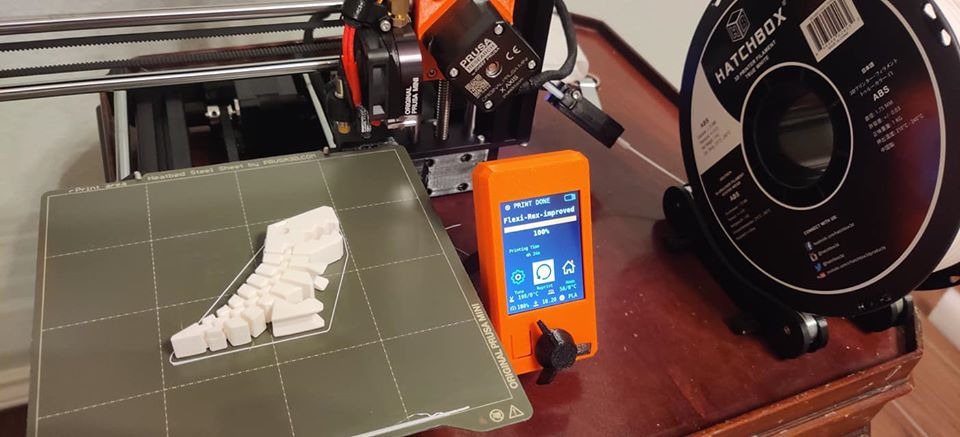

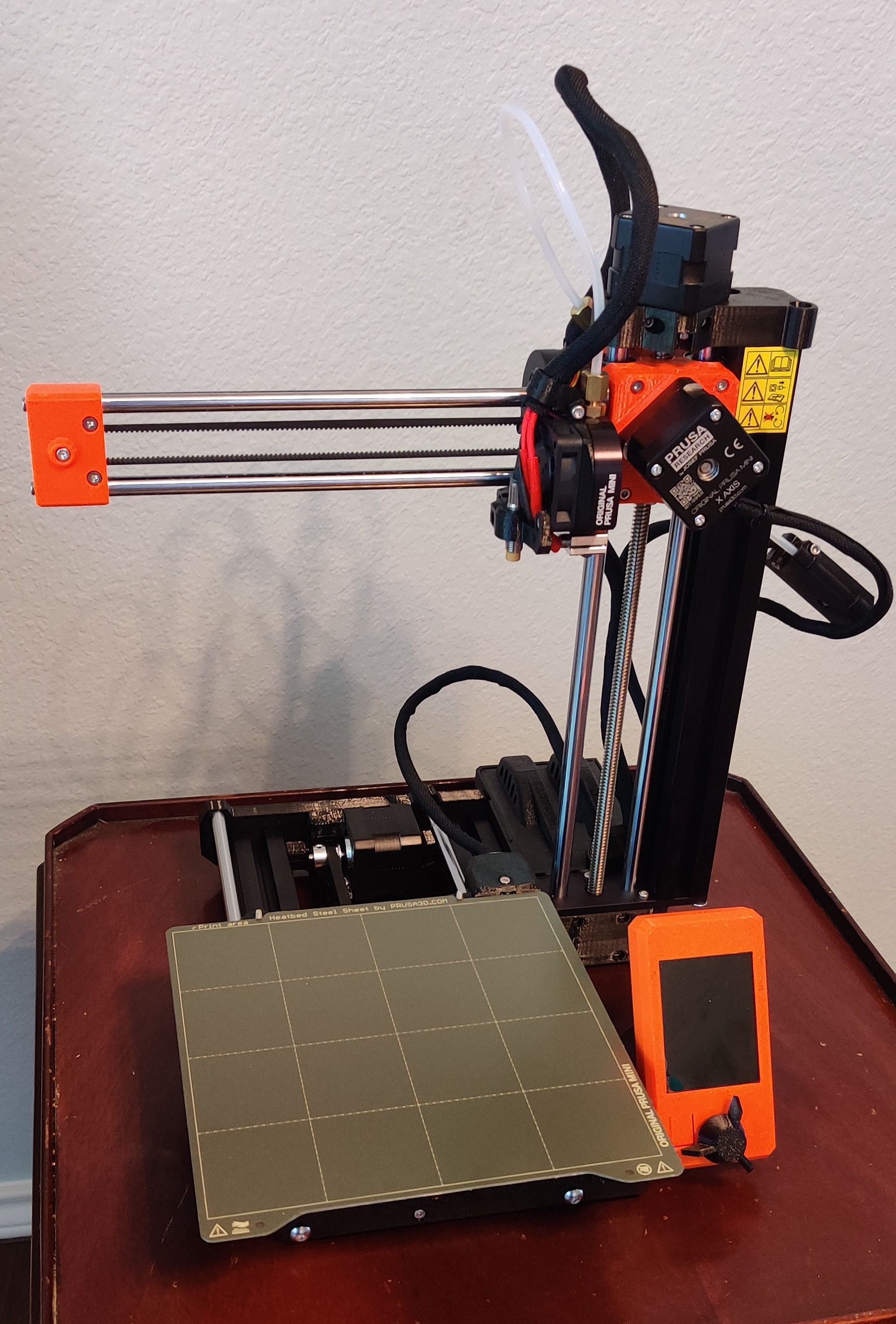

There are many models online, and I had no clue about all of this –I'm a complete noob when related to 3D printing (among other things)– so I checked with a coworker who has one, and he recommended me the brand Prusa. So I got their starter mode: a Prusa Mini.

At this point you may think "If it is your Christmas/New Year's present, how is it that you've had it only for a month?"... and that's a great question. Prusa Mini is a relatively new printer, it has a backorder/waitlist, and coronavirus slowed down production, which ended up with me ordering the printer in January and getting it in June.

The wait was long, and I spent many hours thinking and planning what I could print first: Something cool from Thingiverse? Something that I design myself? Then the printer arrived and suddenly I was out of ideas!

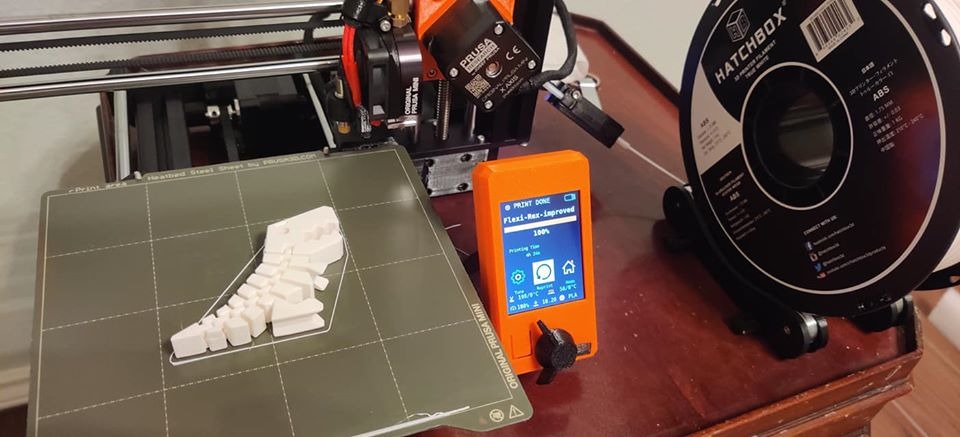

...But my 5-year-old daughter had many. She first helped me assemble the printer, assisted with the calibration and test print, and was quick at suggesting My Little Pony or LOL Surprise searches on Thingiverse 😅

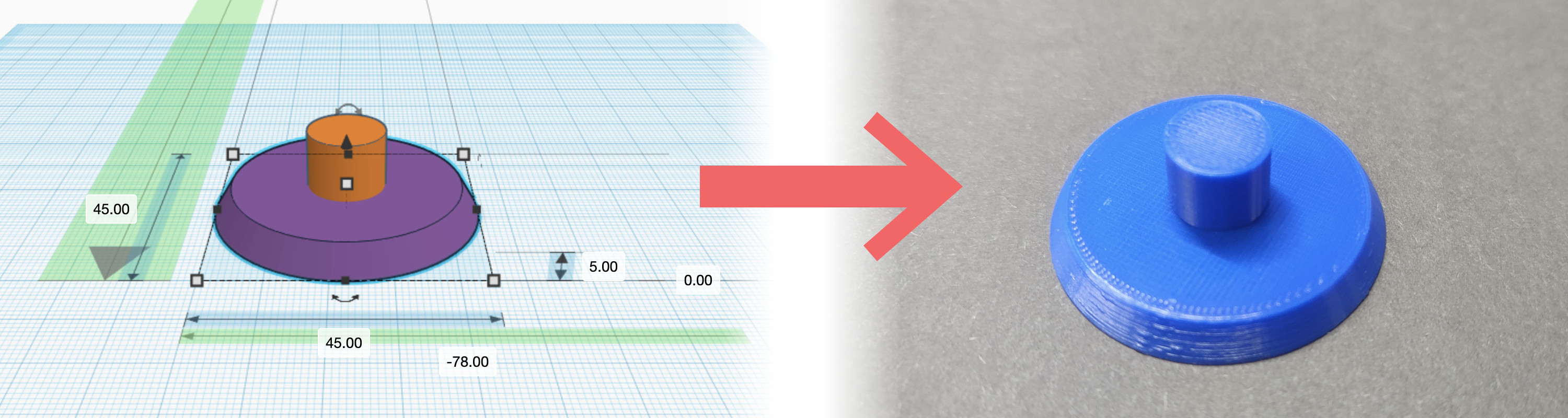

So our first prints were all for kids: cookie cutters, doll accessories, flexi toys (tons of them)... Then a relative saw the prints and said "Hey, could you print something for me?" And that's how we did our first design:

I know it is a really simple thing, but we celebrated it as a big victory. We learned a little of Tinkercad and explore other tools (plus I can do SVG which could be convenient.)

But it was not all easy this month: the printer stopped working because it wasn't pulling the filament in... and that's when I discovered the hobby part of it: 3D printers are not just printing and fun, they require time for learning and maintenance (at least more than what I initially expected).

Luckily for me, a single Allen key was all I needed to disassemble the extruder (a word that I must admit I didn't even know existed before), clean the interior, tighten the screws, et voilà, it worked!

It may sound weird, but 3D printing reminds me a lot of coding: there is a problem, a process, and you get a final result... and there's the feeling of self-fulfillment and achievement, it doesn't matter if it's from fixing the printer or from getting a new model printed.

Next step: combine coding and 3D printing to build something more complex?

As I mentioned above, I'm completely new to 3D printing. I've learned a lot these past few weeks (sometimes the hard way) and I have a lot more to learn. So if you have any advice or recommendation, please share it... I'll definitely need it 😊